Sintered wire mesh is made through a complicated process that creates diffusion bonds at each point of contact with high temperature, high and even pressure. Sintering process can be performed on single layer, multi-layer or multi-layer with perforated metal plate, and offering more advantages compared with woven wire mesh:

● secured opening size

● eliminating edge fraying, easier to fabricate into different sizes, especially for smaller parts

● enhanced mechanical strength, increased thermal and electrical conductivity

● multi-layer sintered wire mesh brings micronic filtration in a harsh environment into reality

● due to its improved structure, sintered wire mesh are cleanable and reusable

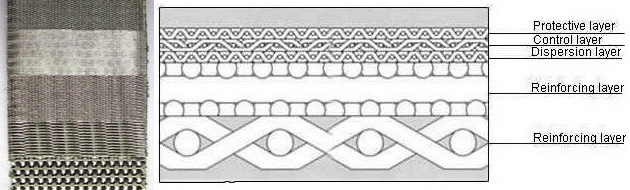

Below is a demonstration of five-layer sintered wire mesh (Dutch Weave):

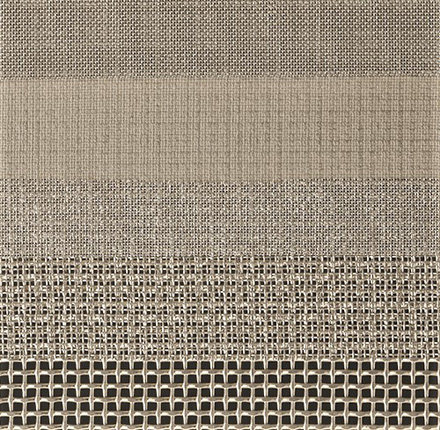

Multi-layer sintered wire mesh can also be made with Plain Wave type:

Adding perforated steel to the outside provides stronger and even more fixed structure as well as longer usage life.

Based on your specific application needs, R & G offers sintered products satisfying your layer, materials, and custom shapes requirements.